QINGDAO SACEME MACHINERY.,LTD.

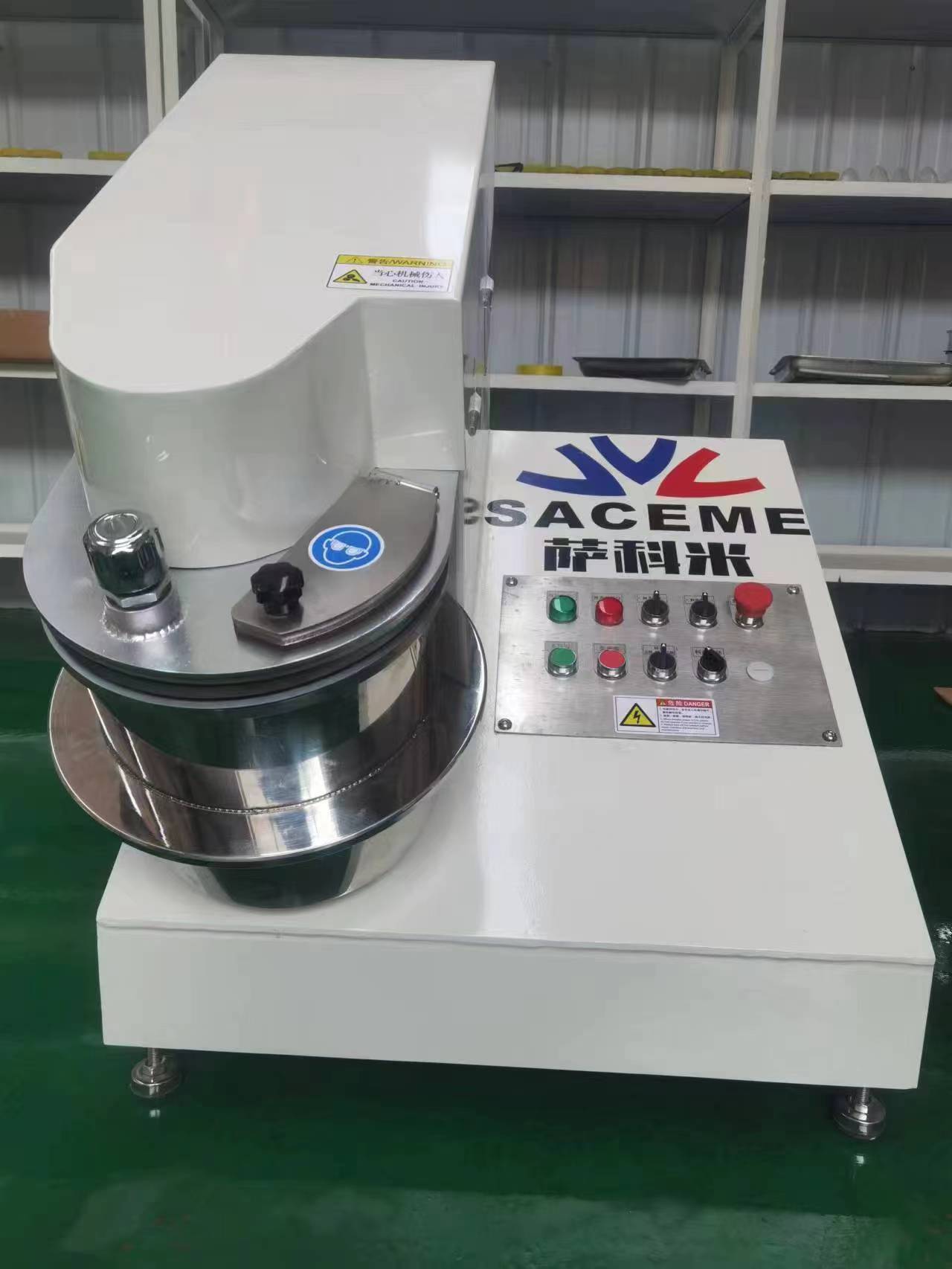

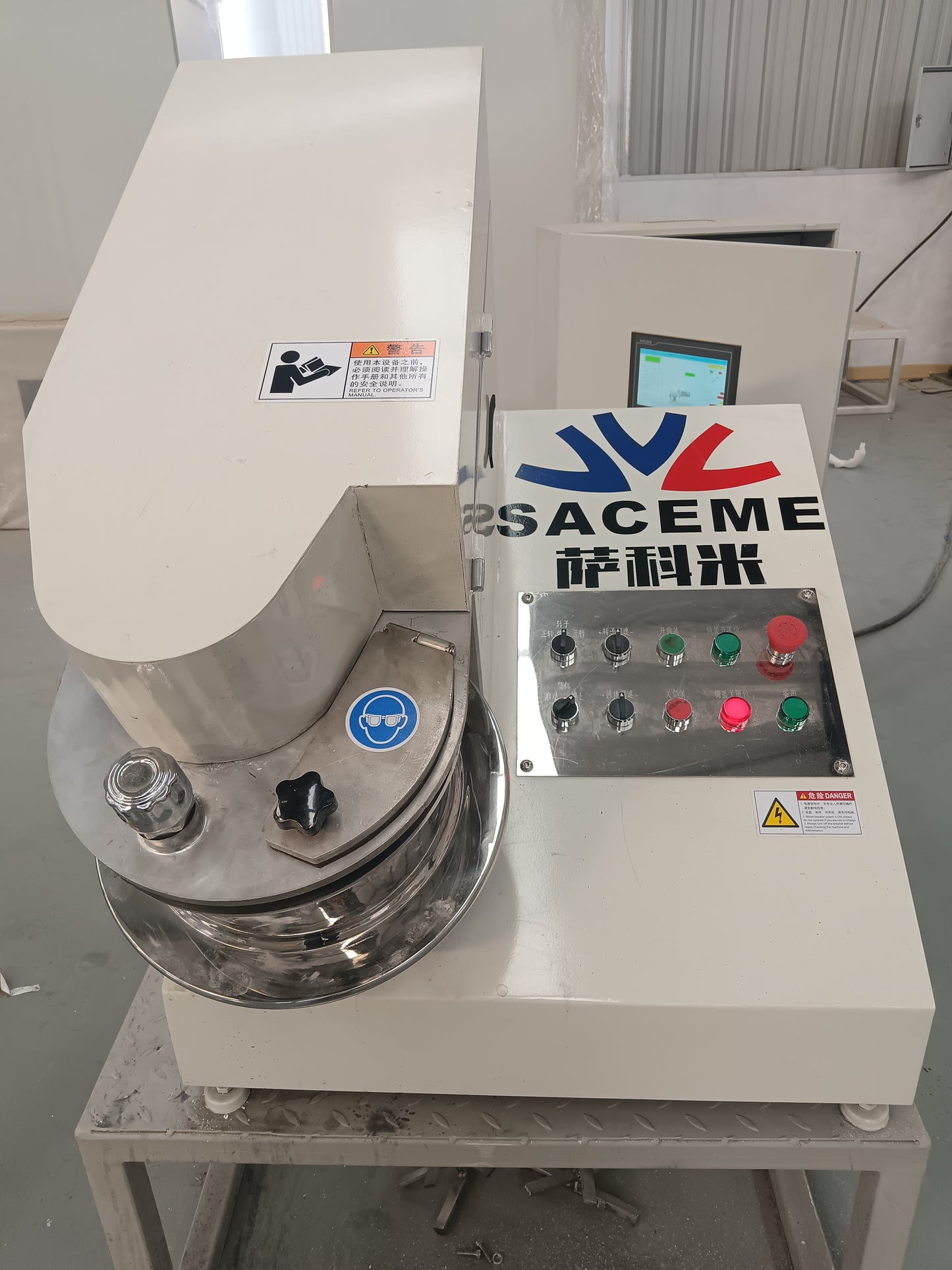

SR02 1-5L Gradient intensive Mixer/Granulator customizable Pelletizing& Mixing Technology|granulating mixer

SR02 1-5L Gradient intensive Mixer/Granulator customizable Pelletizing& Mixing Technology|granulating mixer

laboratory granulator mixer

Category: Granulation and granulation mixers Laboratory granulation mixers for tricky tasks in R&D and small batch production.

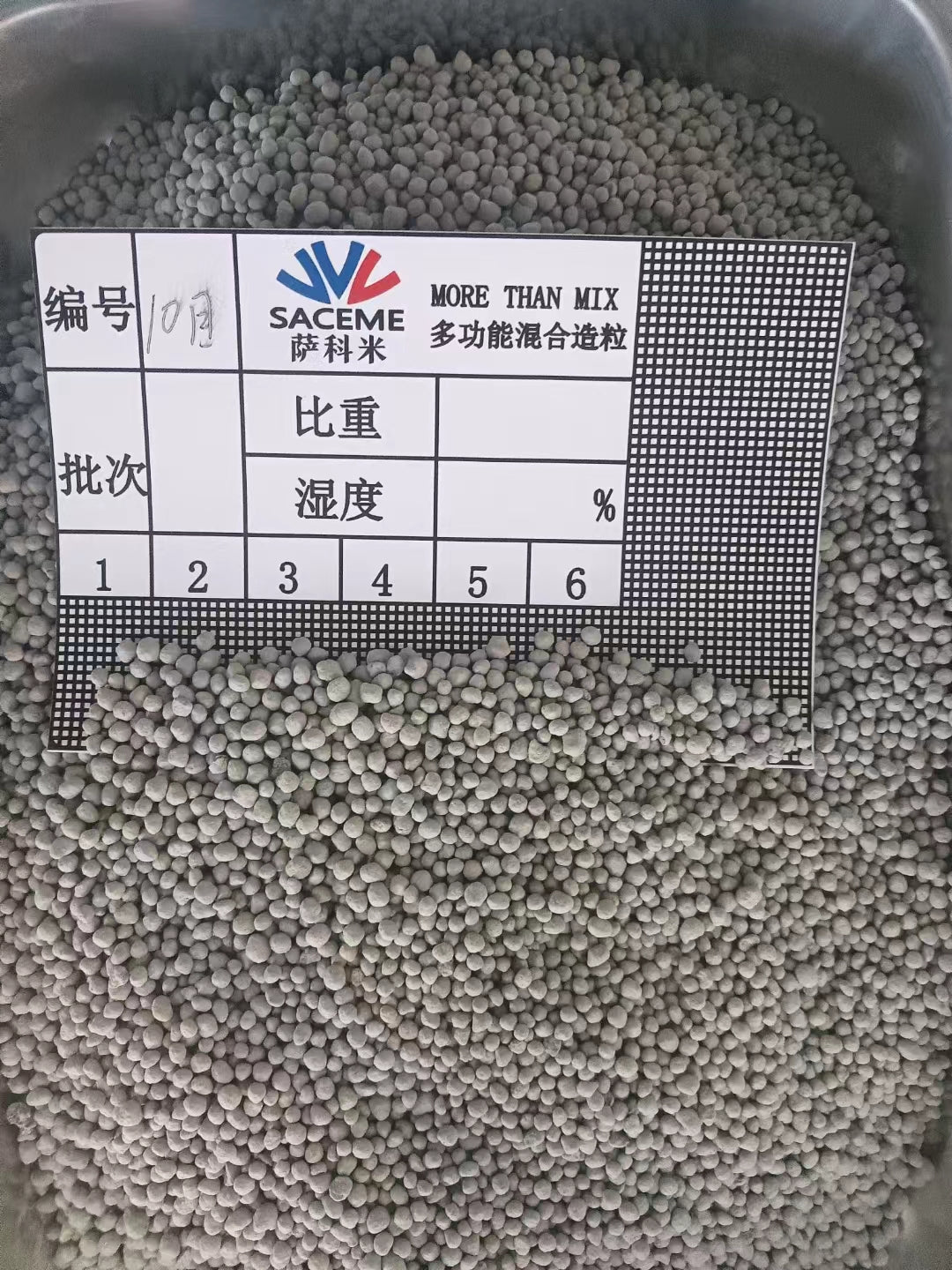

Efficient - high-quality high-speed granulation can be obtained in a very short granulation time.

Unlimited scale-up - test results transferable to industrial scale

The applications of this Lab made grain mixer are different.

Such as: mixing, granulating, coating, kneading, dispersing, dissolving, defibrating, etc.

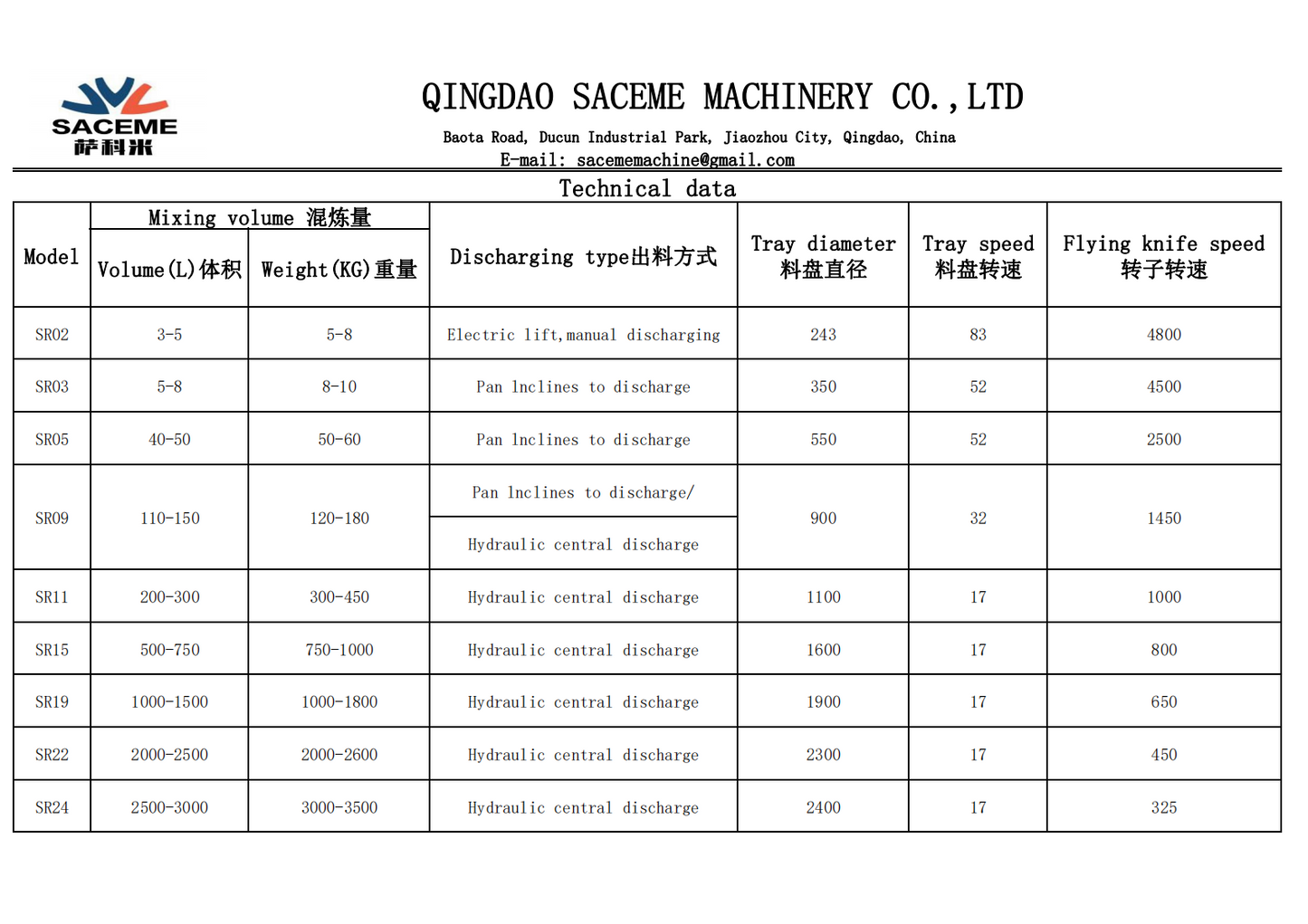

Mixing 5 L, Electric lift,manual discharging,the inclination angle of the cylinder is 30 degrees, with a reserve observation door,, the stirring device rotates at 4800 rpm, and the cylinder 83 rpm, suitable for any powder

Granulator application industry

1.ceramics

Molding materials, molecular sieves, proppants, dental materials, ceramic tools, grinding materials, oxide ceramics, grinding balls, ferrite, etc.

building materials

Brick, expanded clay, perlite and other media, refractory ceramsite, clay ceramsite, ceramsite filter material, ceramsite brick, ceramsite concrete, etc.

2.Glass

Glass powder, carbon, leaded glass powder, waste glass slag, etc.

3.metallurgy

Zinc lead ore, ore, silicon carbide, iron ore, etc.

4.Chemical

Slaked lime, dolomite, phosphate fertilizers, peat fertilizers, mineral materials, chemical fertilizers, phosphate fertilizers, carbon black, etc.

5.Environmental friendly

Filter tower, fly ash, cement powder, tower tower, lead oxide, coal ash, slag, tower tower.

Carbon black, metal powder, zirconia, etc.

Share